Failure Analysis Process

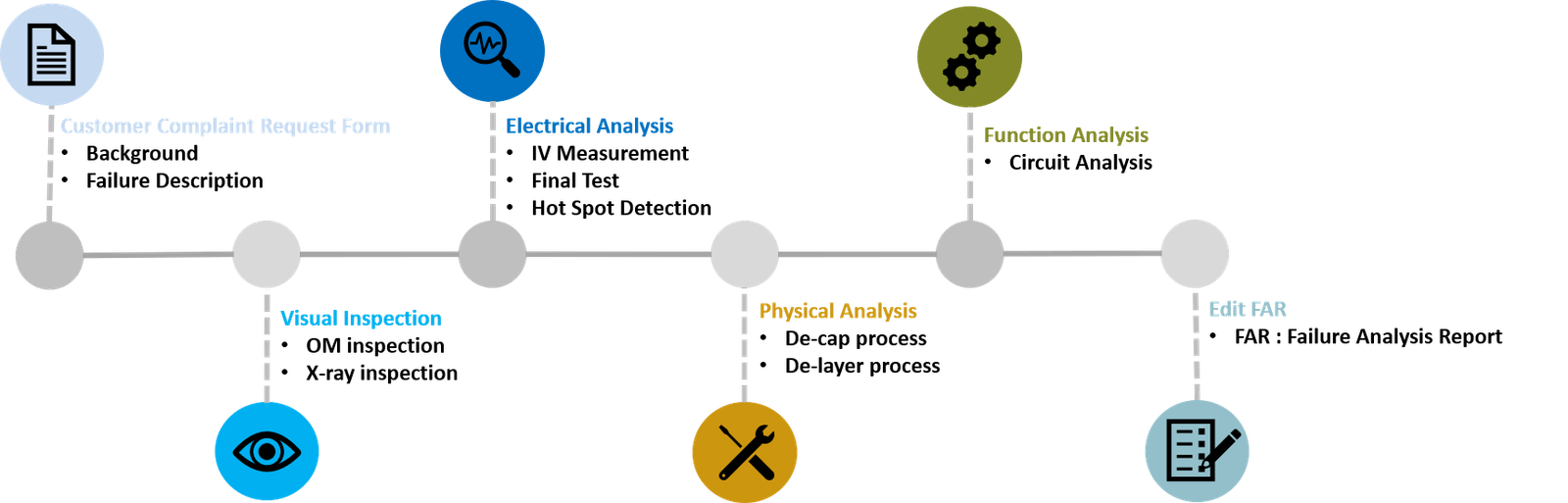

When a product issue is reported, Bravotek promptly initiates a structured Failure Analysis (FA) procedure. The process begins with non-destructive inspection to verify the sample’s visual and electrical characteristics. If destructive analysis is required, it will be conducted only after obtaining the customer’s written approval.

Throughout the analysis, Bravotek develops a case-specific FA plan and collaborates with a qualified third-party laboratory in Hsinchu, utilizing advanced inspection equipment and analytical expertise to ensure efficiency and accuracy.

All data and conclusions are reviewed and validated by Bravotek’s internal engineering team, resulting in a comprehensive FA report with actionable improvement recommendations that ensure both product reliability and customer satisfaction.

Every analysis we conduct begins with responsibility to our customers and to product quality. At Bravotek, failure analysis is not only a technical process but also a commitment to continuous improvement. By transforming each case into valuable insight, we strengthen long-term reliability and build lasting trust with our partners.